Sectors We Work With

Sectors We Work With

Sectors We Work With

FREE storage containers for your scrap metals

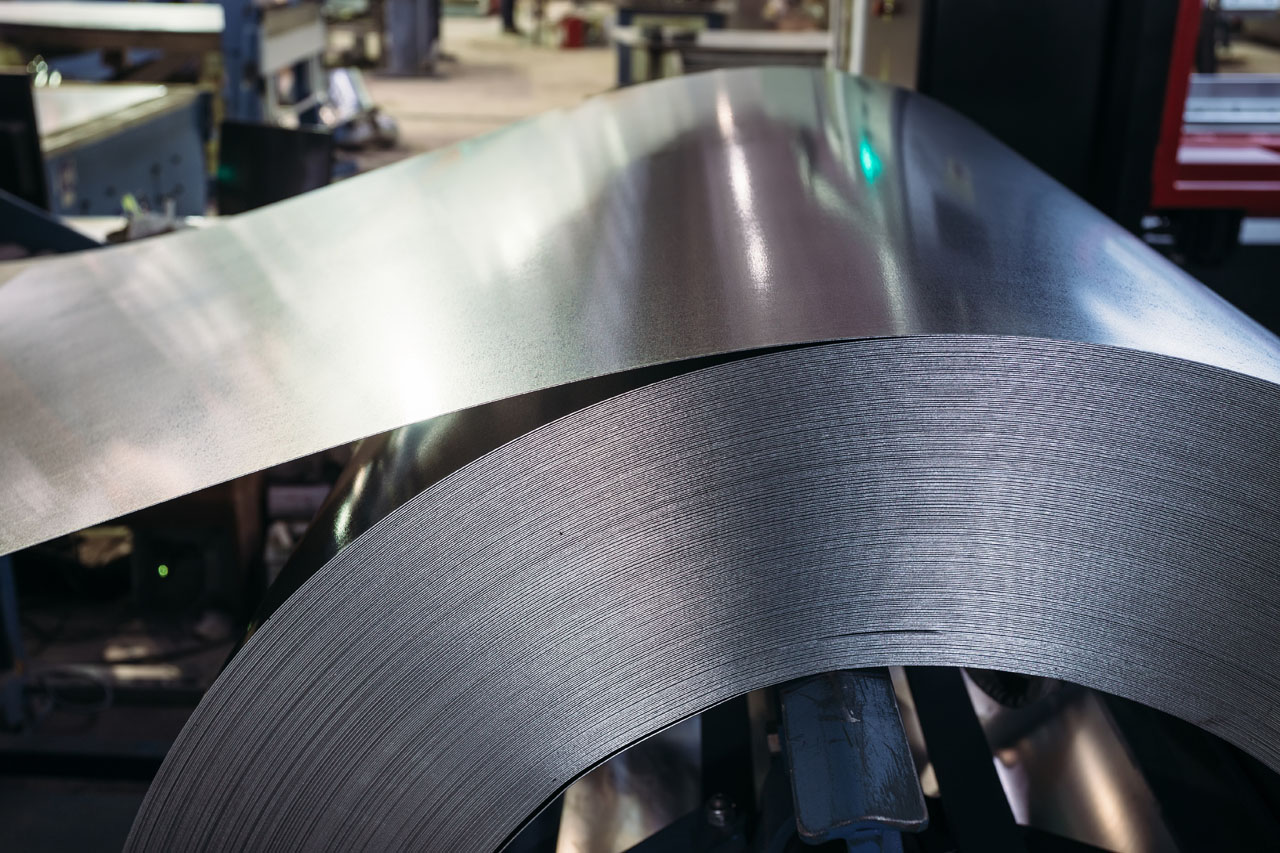

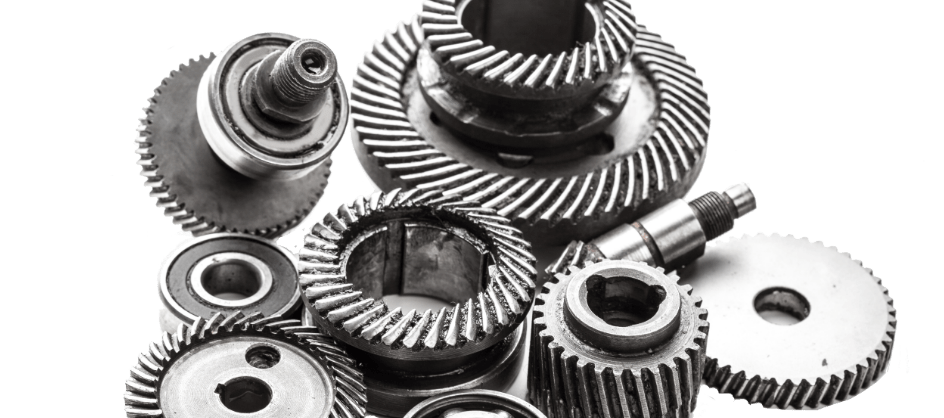

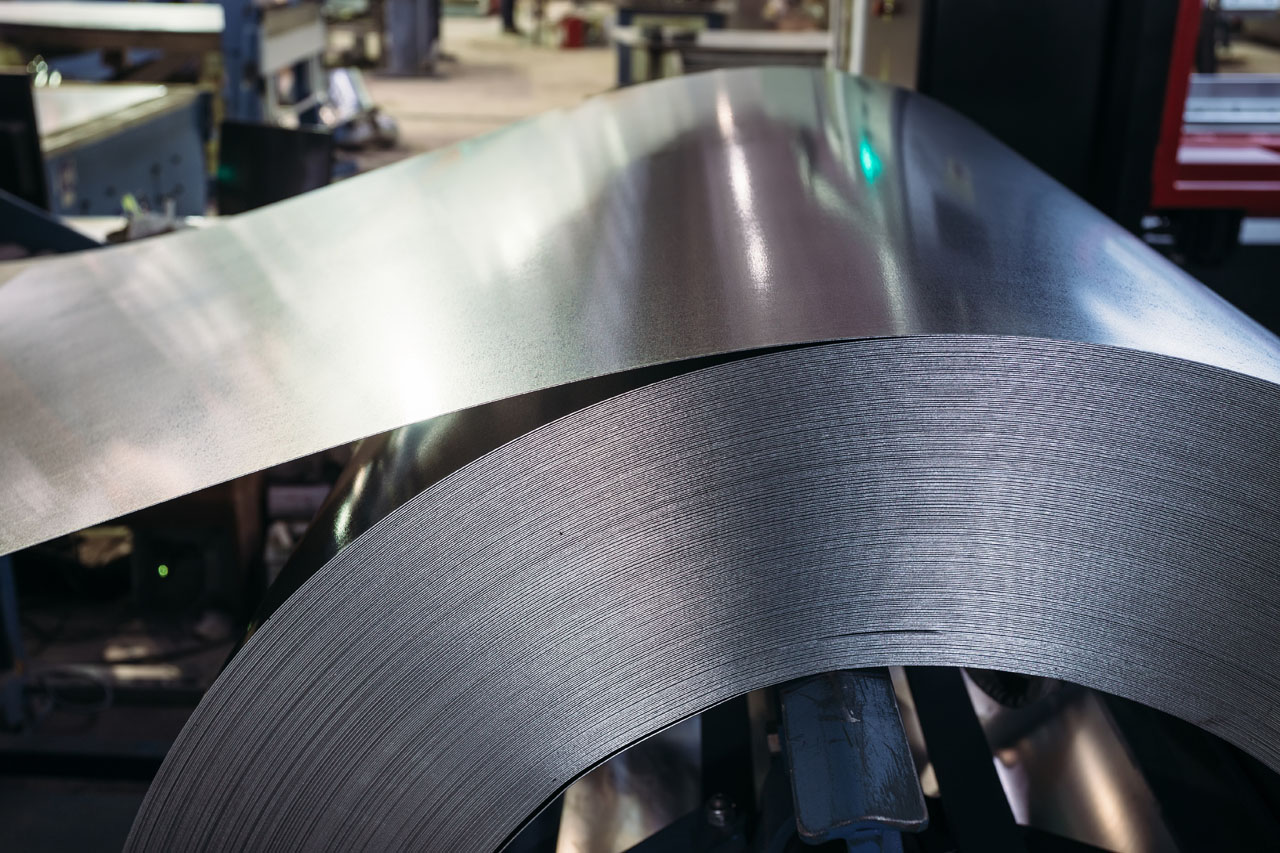

Engineering, manufacturing and fabrication

Using resources efficiently and reducing your business waste at source makes good financial sense and it is better for the environment. The process of recycling your scrap metal can involve space you don’t have, licensing for handling and collection, storage capacity, ensuring you remain compliant with the latest environmental guidance.

2 Recycling Ltd have been handling scrap metals from engineering companies, manufacturers, fabricators and stockists for over 14 years. We are fully licensed with a full range of scrap metals expertise and can give you all the advice you need. Our process is seamless from assessment to collection, grading, weighing and through to invoice providing a complete audit trail throughout the process.

Machining operations during manufacture and fabrication, and engineering processes can produce large volumes of swarf as well as larger offcuts when parts are cut, punched or milled from solid materials. 2 Recycling offers a swarf recycling management system which includes providing smaller scrap metal bins and wheelie bins. Being smaller and more manoeuvrable than bigger containers, they can be placed directly next to the machinery, so less time is spent emptying the machine. It also means that different types of material are sorted as they are processed which provides a higher paid price than if you ended up with mixed materials.

Scrap metal bins are collected and replaced as frequently as your business needs them so that your work site does not grind to a halt and so that they do not take up valuable space.

We can handle all the materials you are generating, whether it is on a daily, weekly or monthly basis:

- Collections are prompt and professionally handled, typically the next working day after the request.

- We have a range of sealed containers to prevent coolant leaks

- Containers with security seals are available.

- Carbide and high-speed steel mini-bins are available.

- Empty bins can be flat packed and stacked when empty.

To find out more about an end-to-end service that can be tailored to your business please call us on 01476 513900.

Using resources efficiently and reducing your business waste at source makes good financial sense and it is better for the environment. The process of recycling your scrap metal can involve space you don’t have, licensing for handling and collection, storage capacity, ensuring you remain compliant with the latest environmental guidance.

2 Recycling Ltd have been handling scrap metals from engineering companies, manufacturers, fabricators and stockists for over 14 years. We are fully licensed with a full range of scrap metals expertise and can give you all the advice you need. Our process is seamless from assessment to collection, grading, weighing and through to invoice providing a complete audit trail throughout the process.

Machining operations during manufacture and fabrication, and engineering processes can produce large volumes of swarf as well as larger offcuts when parts are cut, punched or milled from solid materials. 2 Recycling offers a swarf recycling management system which includes providing smaller scrap metal bins and wheelie bins. Being smaller and more manoeuvrable than bigger containers, they can be placed directly next to the machinery, so less time is spent emptying the machine. It also means that different types of material are sorted as they are processed which provides a higher paid price than if you ended up with mixed materials.

Scrap metal bins are collected and replaced as frequently as your business needs them so that your work site does not grind to a halt and so that they do not take up valuable space.

We can handle all the materials you are generating, whether it is on a daily, weekly or monthly basis:

- Collections are prompt and professionally handled, typically the next working day after the request.

- We have a range of sealed containers to prevent coolant leaks

- Containers with security seals are available.

- Carbide and high-speed steel mini-bins are available.

- Empty bins can be flat packed and stacked when empty.

To find out more about an end-to-end service that can be tailored to your business please call us on 01476 513900.